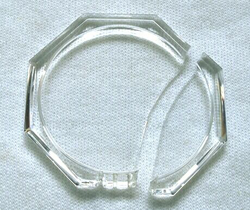

Side view showing groove

This photo shows an inset rim or groove into which a slip ring was inserted from the top. The slip ring was compressed smaller and then released inside the groove.

The movement was then to be dropped into place inside and on top of the slip ring. The slip ring had 6 places to accept screws. The

movement was then screwed to the slip ring which held the movement in place.

This concave groove needed to be perfectly round and of exact tolerances and contour for the slip ring to fit. If the groove was too small, the ring would not fully open after being inserted. If the groove was too wide, the ring would expand too wide.

The new piece also needed 3 drill holes from the outer edge to the inner edge. One for the stem to pass through and two for the

brackets of the bail over the stem.

The outer dimensions of the watch case measures 1 3/4" x 1 3/4". The thickness of the quartz is 4.0 mm and the thinnest part in the center is .9 mm.

The back of the watch case acts as a quartz window through which the inner mechanical workings of the movement can be viewed. I wish I had a picture of that, it was impressive.